About Boiler Maintenance & Research Institute

With each passing day the importance of boiler technocrats in each and every industry is increasing in direct proportion to demand. After liberalization of Indian economy the demands for qualified boiler

technocrats has increased manifold because multinationals are getting interested in opening of new industries in India where the scope of boiler technicians (boiler 2nd class, 1st class & boiler operational engineers)

has increased significantly. Thus boiler technicians and engineers have an opportunity to serve in chemical related industries, power plants,steel plants, paper industries, oil refinery industry, sugar, textile, leather

and agro-based industry, shipping corporation of India and abroad.

.

Thus we at SDEAS rightly judge the need of the hour and set on the mission to produce the best technocrats in the field of Boiler and Power Plant technology by providing the theorytical and practical through the full time self developed training course BOILER MAINTENANCE ENGINEERING..

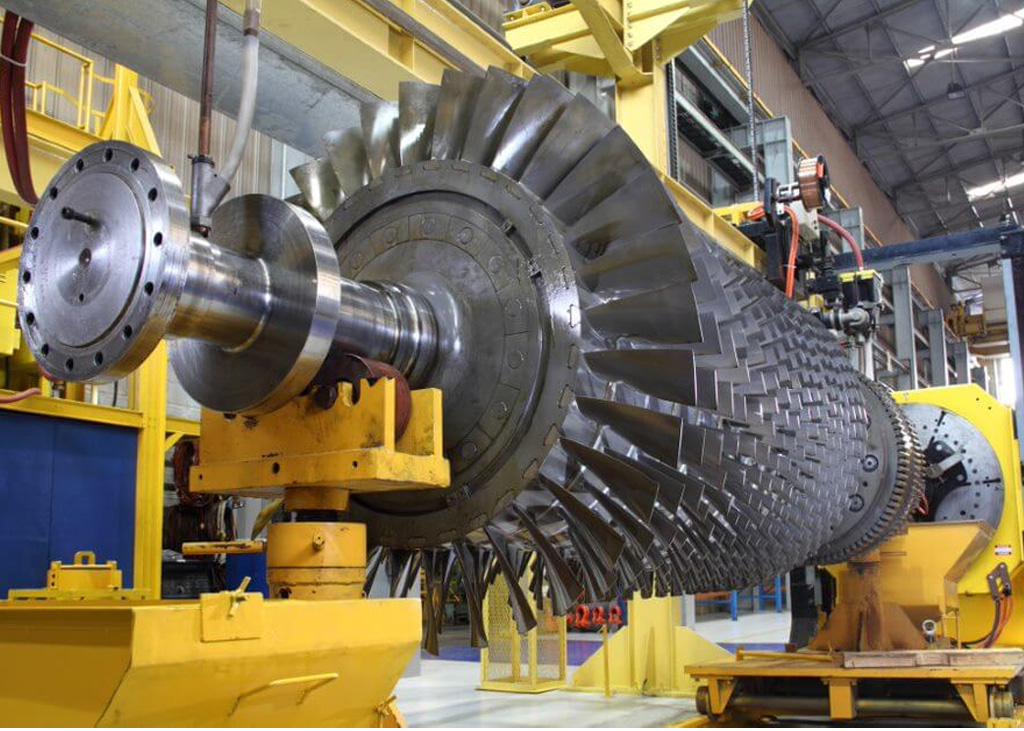

It is the only boiler training institute in India which is time tested in this line since 1990, to prepare aspirants to be accrue with highly skilled boiler engineers/ operators and technocrats to face the challenges in first growing industrialization in the country. It's workshops are well equipped with different types of boiler models, training manuals and reference books on boiler maintenance and operations.We are also have a good tie up with the Industries having Power plants and Boilers . This course, first of its kinds in India was started by some enthusiastic qualified promoter and was assisted by a team of highly experienced engineers, power plants professionals/consultants / engineers, boilers technocrats and senior professors under central boiler maintenance research trust. Career in BME is an attraction of the new generation because it provides job opportunity prosperity in India and abroad. The pass out students can join in state govt./ central govt./ and large private sector undertakings..

The training programs are imparted to individual students in different boiler based industries, boiler manufacturing industries to make them expert in operation/ maintenance/ erection and fabrications of different types of water tube boilers. This practical training is correlated with course syllabus of each theory paper. During Industrial visit program and regular impact training program each trainee observe various types of boiler operation and function, they can understand theoretical phenomenon by practical simulation. After completion of the training each trainee is bound to do a project on the basis of the training programme.